.png)

.png)

BELLSTONE offers a wide range of mould polishing stones excellent for removing machining marks and spark erosion grains for preparing the surface for final polishing. Finer grits available makes it possible to prepare the right surface for Diamond polishing eliminating the requirement of using emery papers, thus making the polishing process fast and free of defects like waviness

BELLSTONE offers a wide range of mould polishing stones excellent for removing machining marks and spark erosion grains for preparing the surface for final polishing. Finer grits available makes it possible to prepare the right surface for Diamond polishing eliminating the requirement of using emery papers, thus making the polishing process fast and free of defects like waviness

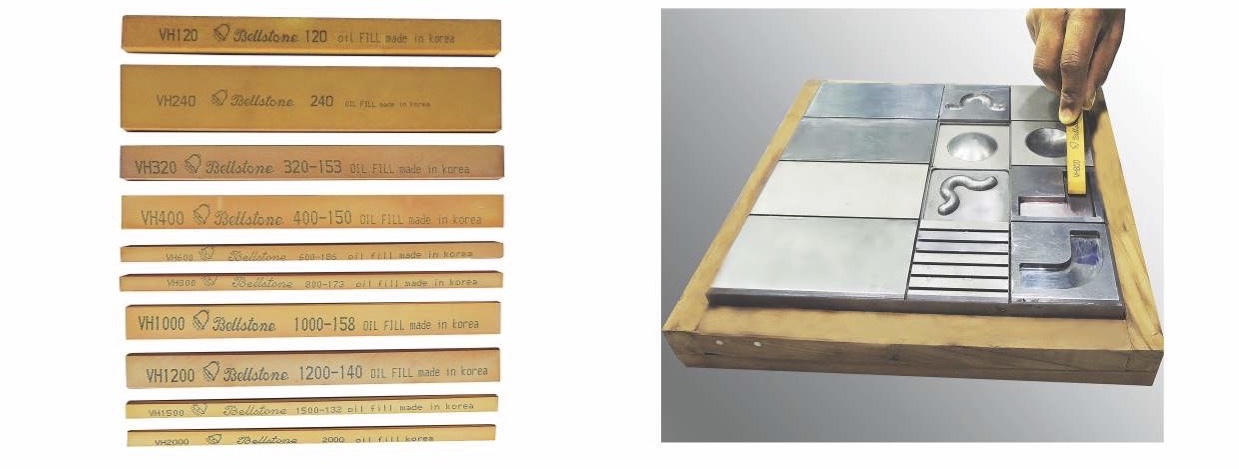

VH Series Mould Polishing Stone

Consisting of premium grade of white aluminium oxide (WA), VH series stones are manufactured by a vitrified process. It has the right mix of abrasives, bonding and curing additives that imparts excellent cutting properties. The edges resist breaking down thus giving high cutting efficiency and very low wear rate. Used for polishing larger surfaces, edges and deep grooves, these can be dressed to polish virtually any shape or profile. Recommended for use on carbon steel, alloy tool steel, stainless steel, it virtually covers all kind of mould steels.

PLASSTEZE Polishing Stone

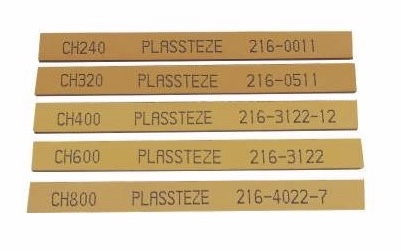

CH Series Mould Polishing Stone

Made of premium aluminium oxide, CH stones are the Economy Series Polishing Stones manufactured exclusively for polishing Moulds and Dies. The rough grits (240-320) are used by for removing EDM grains and machining marks. Finer grits (400~800) are recommended for further polishing to prepare the surface for Diamond polish.

Combination Stones

GC600/C240

Our range includes a special combination stones-a combination of FIne (GC600) and Coarse (C240) in sizes convenient to hold and polish. Excellent for big moulds and dies, plates, hot runner manifold, machine slides. Used for numerous applications like cleaning, deburring, chamfering, polishing,...

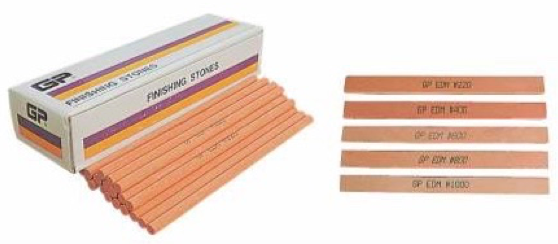

More Options for polishing stones available now:

Size (mm): 6x150, 6x6x150, 13x6x150, 13x3x150

Grit # 180, 220, 320, 400, 600, 800, 1000

Use with PLASSTEZE stoning oil for best results

Stoning Oil - SO 500

An oil based thin flowing lubricant for use with polishing stones and diamond compounds while polishing moulds, dies or any other metal parts

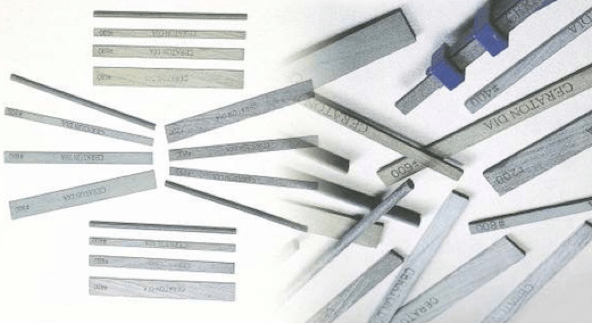

Ceramic Diamond Stones

Made of diamond abrasives and ceramic fibres bonded toge ther with thermosetting resin. Diamond's cutting performance in combination with the superior tensile strength of the ceramic fibre makes Ceramic Diamond Stone a perfect lapping tool. The ordinary ceramic fibre stone is efficient only to lap by its tip, while the ceramic diamond stone works well with any sides or surface. Materials those are difficult to be grounded by ordinary ceramic stone, can easily be polished using a ceramic diamond stone. It is ideal for lapping all kind of hardened steel, EDM surface, Tungsten Carbide, Ceramics and Glass efficiently.

ther with thermosetting resin. Diamond's cutting performance in combination with the superior tensile strength of the ceramic fibre makes Ceramic Diamond Stone a perfect lapping tool. The ordinary ceramic fibre stone is efficient only to lap by its tip, while the ceramic diamond stone works well with any sides or surface. Materials those are difficult to be grounded by ordinary ceramic stone, can easily be polished using a ceramic diamond stone. It is ideal for lapping all kind of hardened steel, EDM surface, Tungsten Carbide, Ceramics and Glass efficiently.

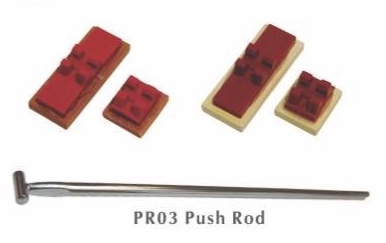

Polishing Stones on Plastic Shoes

Excellent for polishing flat and large surfaces with Polishing/Filing machines.  Used with our specially designed Push Rod.

Used with our specially designed Push Rod.

B-152, Mayapuri Industrial Area, Phase-1, New Delhi, 110 064, India

T: 011 43738825

M: +91 98102 99598

E: plassteze@plassteze.com

M: +91 9958100847

E: pune@plassteze.com

M: +91 99581 00895

E: chennai@plassteze.com

M: +91 99581 00527

E: guj@plassteze.com