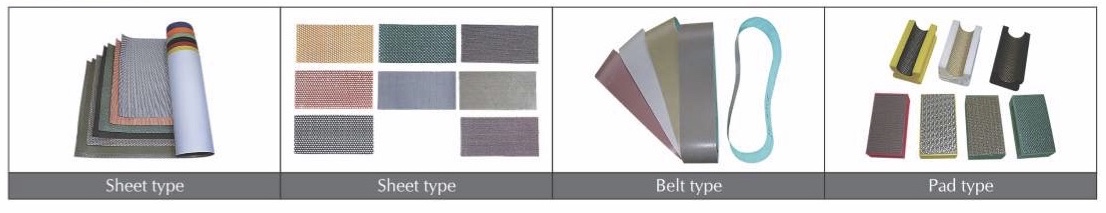

DIAMOND FOIL:

DIAMOND CLOTH:

The application of diamond power on a flexible cloth has allowed the development of a new generation of diamond tools. This tool performs a more aggressive cutting action than any other abrasive tools, thanks to its flexibility and to the spacing between islands, the diamond cloth can be easily cut with a scissor.

Applications:

B-152, Mayapuri Industrial Area, Phase-1, New Delhi, 110 064, India

T: 011 43738825

M: +91 98102 99598

E: plassteze@plassteze.com

M: +91 9958100847

E: pune@plassteze.com

M: +91 99581 00895

E: chennai@plassteze.com

M: +91 99581 00527

E: guj@plassteze.com